Production Timber & Wooden Pallet Boards for Concrete Pavers

RHINO

COMPOSITE PALLETS

Worldwide supplier of hardwood production boards for concrete block machines

What are production boards for concrete blocks?

Production boards for concrete blocks are large rectangular slabs made from wood, steel or plastic. They are used in manufacturing concrete products, and their efficient transport inside a concrete block factory.

Fresh semi wet concrete is poured in specific steel moulds, that are made to vibrate on the production board in concrete block machines. Based on the shape of the mould, concrete sets to make various products like concrete blocks, pavers, bricks and kerb stones etc..

RHINO production boards are offered in all sizes, and cater to all concrete block machine applications. RHINO production boards are manufactured to exact dimensions based on the specification of concrete block machine manufacturers.

WHY RHINO HARDWOOD PRODUCTION BOARDS?

Production board pallets come in various types of materials like steel, plastic, softwood or hardwood and are generally large rectangular slabs that are used to manufacture concrete blocks.

Clients who are using RHINO boards do notice better block densities, better strengths, equal block heights, faster cycle times, better filling and compaction, better control production process, power (energy) reduction and the possibility to recalibrate the RHINO boards up to 3 times during use. The board is made of waterproof resin and hardwood fibres and therefore very useful in climates with high humidity. RHINO boards are one piece boards without gaps or steel C-profiles or tie rods.

Refurbishable PRODUCTION BOARDS

Why use expensive steel pallets when you can achieve the same longevity at a fraction of the cost? Our pallets can be re-furbished to near new condition.

- Re-sanding: Sand back up to 3 times in house to breathe new life into your production boards

- Re-furbishing: After a long, productive service life, send the boards back to us for a full re-furbish and we’ll ship them back to you

Precision

Customised dimensions that fit your concrete block machine seamlessly. We work with you to create samples for test runs so we can ensure a perfect fit.

Our production boars can be used in a variety of concrete black machines such as MASA, OMAG, Prensoland, HESS, KVM and Rekers to name a few*.

* All trademarks are owned by their respective owners and we do not claim any association with any of these companies.

Durability

Scorned by cheap GMT plastic and softwood production boards in the past? We put a lot of thought into ensuring durability in every aspect of our production boards so you can have peace of mind.

Precision

Customised dimensions that fit your concrete block machine seamlessly. We work with you to create samples for test runs so we can ensure a perfect fit. Our production board pallets can be used in a variety of concrete black machines such as MASA, OMAG, Prensoland, HESS, KVM and Rekers to name a few*. * All trademarks are owned by their respective owners and we do not claim any association with any of these companies.

Durability

Scorned by cheap GMT plastic and softwood pallets in the past? We put a lot of thought into ensuring durability in every aspect of our production board pallets so you can have peace of mind. Here’s how we achieve durability in our productions board pallets:

Long Service Life

Why use expensive steel pallets when you can achieve the same longevity at a fraction of the cost? Our pallets can be re-furbished to near new condition.

- Re-sanding: Sand back up to 3 times in house to breathe new life into your production boards

- Re-furbishing: After a long, productive service life, send the pallets back to us for a full re-furbish and we’ll ship them back to you

Precision

Customised dimensions that fit your concrete block machine seamlessly. We work with you to create samples for test runs so we can ensure a perfect fit.

Our production board pallets can be used in a variety of concrete black machines such as MASA, OMAG, Prensoland, HESS, KVM and Rekers to name a few*.

Durability

Scorned by cheap GMT plastic and softwood pallets in the past? We put a lot of thought into ensuring durability in every aspect of our production board pallets so you can have peace of mind. Here’s how we achieve durability in our productions board pallets:

Manufactured from high-grade densified engineered hardwood to give them superior strength and durability.

Minimal deflection and uniform vibration transmission

Hard-wearing lamination on top and bottom surfaces ensures excellent resistance to abrasion by production boards during concrete block production.

The production boards are single solid boards with no joints or gaps that could be a potential weak point. Also ensures that the concrete sets evenly.

Treated individually with industrial-strength waterproof resin, hardwood fibres are pressed under very high pressure and temperature. This creates exceedingly strong production boards for concrete blocks.

The core and sides are fortified against moisture

Reinforced c profile, chamfered edges and all sides are impregnated with a waterproof polyurethane based coating

Ready to try a sample?

Sustainable Practises

Specifications

What are the technical specifications of our production boards for concrete block machines?

- ParameterSpecifications

- DimensionsCustom dimensions available with thickness between 25 - 70mm

- MaterialDensified hardwood

- SurfaceIndustrial fabric, synthetic film or polypropylene

- CoreCompressed multi-layered hardwood veneers

- ReinforcementsTop and bottom protective layers steel mesh on both sides of core

- Edge ProtectionImpregnated with a waterproof polyurethane based coating Galvanised steel C profile Chamfered edges

Product Range

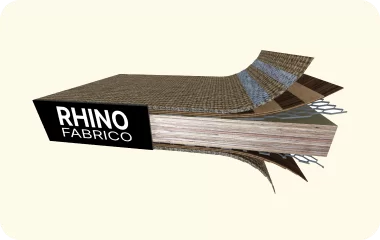

RHINO FABRICO

The top and bottom surfaces of this board are protected by five layers of industrial fabric. The fabric is impregnated with high strength thermosetting waterproof resin.

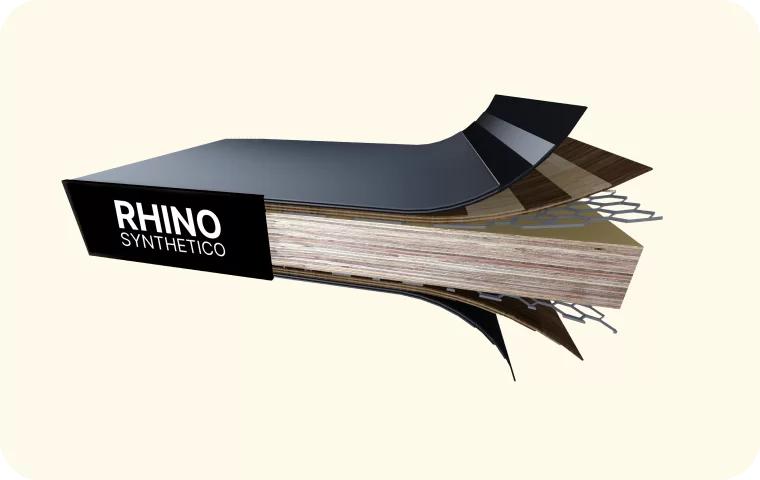

RHINO SYNTHETICO

The top and bottom surfaces of this production board are protected by multiple layers of synthetic films coated with high strength thermosetting waterproof resin.

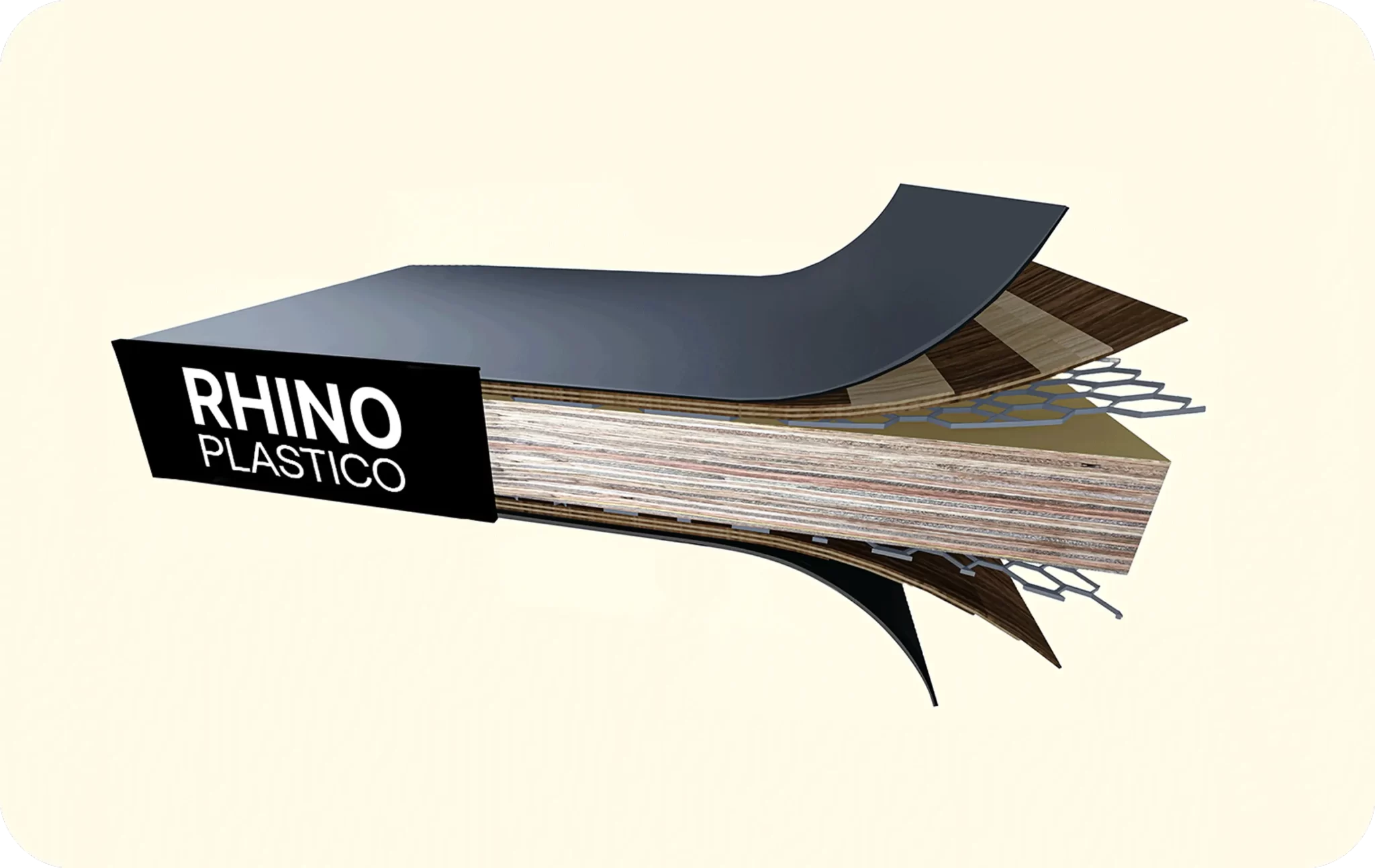

RHINO PLASTICO

The top and bottom surfaces of Rhino Plastico are reinforced with a thick sheet of polypropylene.

Ready to try a sample?

Contact Us

Please contact us by filling out the form below and we’ll reach out to you within 1 business day.